SX4 Adjustable Comb Supplement

SX4 Adjustable Comb Supplement

Winchester is a registered trademark of Olin Corporation.

ALWAYS KEEP THE MUZZLE POINTED IN A SAFE DIRECTION. BEFORE STARTING ADJUSTMENT OR DISASSEMBLY PROCEDURES, ENSURE THE “SAFETY” IS IN THE ON SAFE POSITION. OPEN THE ACTION AND VISUALLY INSPECT THE CHAMBER TO BE ABSOLUTELY CERTAIN THE FIREARM IS COMPLETELY UNLOADED. FAILURE TO FOLLOW THIS WARNING COULD RESULT IN SERIOUS INJURY OR DEATH.

PLEASE READ AND UNDERSTAND ALL INSTRUCTIONS AND WARNINGS IN THE OWNER’S MANUAL SUPPLIED WITH YOUR SHOTGUN AND THOSE FOUND IN THIS SUPPLEMENT BEFORE USING YOUR SHOTGUN. FAILURE TO FOLLOW THESE INSTRUCTIONS, OR FAILURE TO FOLLOW ANY SAFETY WARNING, MAY RESULT IN INJURY OR DEATH TO YOURSELF OR OTHERS, OR MAY CAUSE DAMAGE TO YOUR FIREARM.

Certain Super X® 4 models include interchangeable combs that allow you to fine tune drop at comb and achieve proper alignment with iron, electronic or optical sights. The comb height is adjusted by installing one of the included combs.

If your shotgun owner’s manual is missing, contact the Winchester Repeating Arms customer service department immediately at (800) 333-3288 for a free copy, or download one at winchesterguns.com.

WEAR EYE PROTECTION WHEN DISASSEMBLING AND CLEANING YOUR SHOTGUN TO PREVENT SPRINGS, SPRING-LOADED PARTS, SOLVENTS, OR OTHER AGENTS FROM CONTACTING YOUR EYES, RESULTING IN INJURY.

DISCHARGING FIREARMS IN POORLY VENTILATED AREAS, CLEANING FIREARMS, OR HANDLING AMMUNITION MAY RESULT IN EXPOSURE TO LEAD AND OTHER SUBSTANCES KNOWN TO CAUSE BIRTH DEFECTS, REPRODUCTIVE HARM, AND OTHER SERIOUS PHYSICAL INJURY. HAVE ADEQUATE VENTILATION AT ALL TIMES. WASH HANDS THOROUGHLY AFTER EXPOSURE.

ALWAYS KEEP THE MUZZLE POINTED IN A SAFE DIRECTION. BEFORE PERFORMING ADJUSTMENT PROCEDURES, ENSURE THE “SAFETY” IS IN THE ON SAFE POSITION. OPEN THE ACTION, UNLOAD THE MAGAZINE, AND MAKE CERTAIN YOUR SHOTGUN IS COMPLETELY UNLOADED. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

Comb Height Adjustment

Comb Height Adjustment

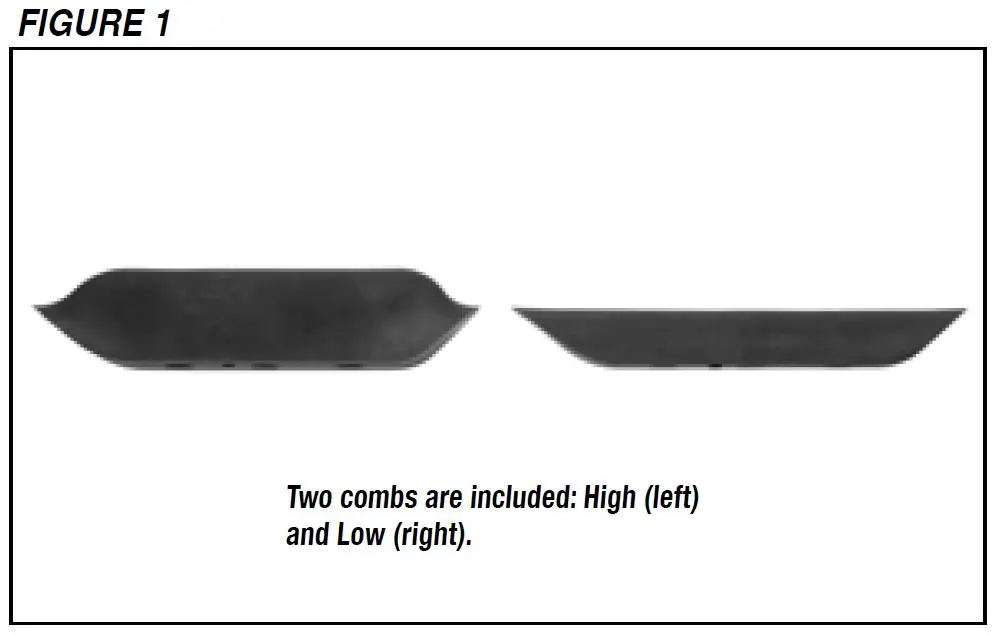

Two combs are included with the shotgun to adjust for correct eye-to-sight alignment (Figure 1). The low comb is ideal for use with the factory sights. The high comb is optimized for use with optics mounted to the rail on top of the receiver. To change combs perform the following operation:

1. Ensure the “safety” is in the on safe position and the shotgun is completely unloaded.

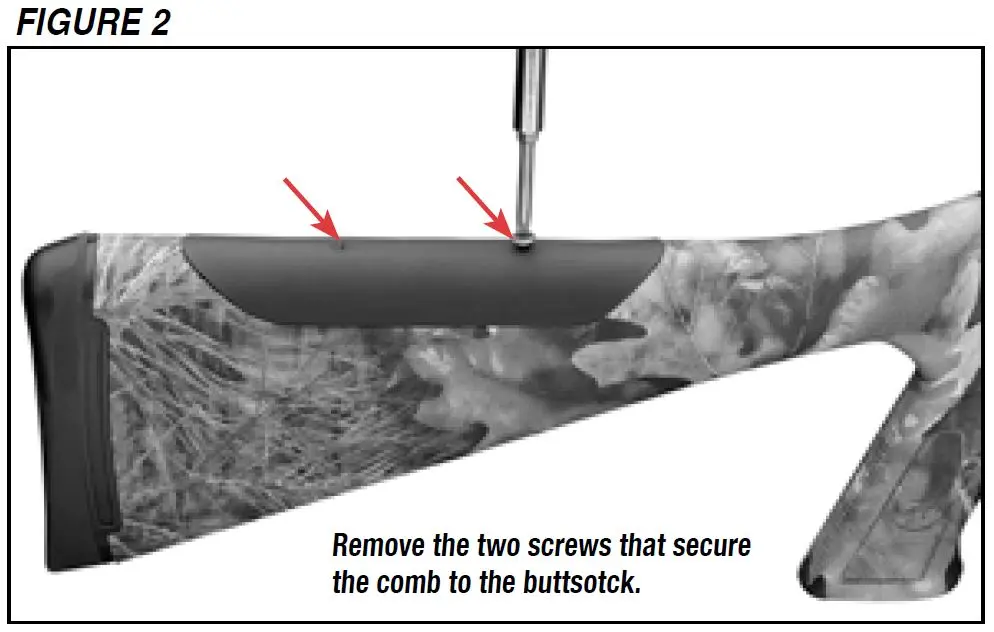

2. Two screws secure the comb to the stock (Figure 2). Insert a #2 cross tip screwdriver into the holes and turn the screws counterclockwise until they can be removed from the comb. To prevent damage to the comb, place a small amount of petroleum jelly on the screw access slits.

3. With the two screws removed, the comb can be removed from the stock.

IMPORTANT: In addition to the screws, the comb is secured to the stock using two fixed mounting bosses. The tight fit of the comb to the bosses prevents the comb from moving under recoil. To loosen the comb from the bosses, carefully rock the comb from side to side while carefully lifting it from the stock.

NOTICE: DO NOT PRY ON THE COMB OR THE STOCK. YOU MAY DAMAGE THE SHOTGUN.

4. Place the new comb on the stock, ensuring that it is oriented correctly so the contours on the front and rear of the comb match those on the stock. Press down firmly to secure the comb to the mounting bosses. Shoulder the shotgun to determine if the new comb comfortably provides correct eye-to-sight alignment.

Remember to always keep the muzzle pointed in a safe direction, ensure the safety is in the “on safe” position, and the shotgun is completely unloaded.

5. If you are satisfied with the comb height, start the screws through the comb and into the holes in the stock using the screwdriver. Turn the screws clockwise to tighten. Do not overtighten the screws.

PARTS, SERVICE, REPAIR, AND QUESTIONS

PARTS, SERVICE, REPAIR, AND QUESTIONS

If your Winchester firearm should require service or repair, we suggest first contacting a Winchester Repeating Arms Authorized Repair Center. To locate an Authorized Repair Center visit winchesterguns.com, contact our customer service department, or ask your local Winchester Repeating Arms dealer. You may also send your firearm to the Winchester Repeating Arms Service Facility in Arnold, Missouri. In order to avoid service delays, do not send your firearm directly to our service facility without authorization from one of our service specialists.

Parts listings, a list of Authorized Repair Centers, service procedures, service/repair form, and general product information are on the web at winchesterguns.com.

When returning your firearm for service, you must do the following:

1. Be sure it is completely unloaded.

2. Remove any optics, optic mounts or other accessories.

3. Package it securely in a cardboard container.

4. Enclose the service/repair form available at winchesterguns.com or a letter that clearly describes the trouble experienced, the ammunition used, and the repairs desired. Also include your name, e-mail address (if possible), and a daytime phone number where you can be reached.

5. Never return ammunition with your firearm. It is against postal and most commerce regulations.

PARTS, SERVICE, REPAIR STATUS, AND TECHNICAL QUESTIONS:

Winchester Repeating Arms Parts and Service

3005 Arnold Tenbrook Road

Arnold, MO 63010-9406

Phone: (800) 322-4626

GENERAL PRODUCT AND HISTORICAL QUESTIONS:

Winchester Repeating Arms Customer Service

275 Winchester Avenue

Morgan, UT 84050-9333

Phone: (800) 945-5237

customersupport@winchesterguns.com

WARNING: PARTS ARE MADE FOR WINCHESTER BRAND FIREARMS MANUFACTURED BY OR FOR WINCHESTER REPEATING ARMS, AND SHOULD NOT BE USED IN OTHER FIREARMS, EVEN THOUGH MODELS MAY BE SIMILAR. IMPROPERLY FITTED PARTS MAY BE DANGEROUS. FAILURE TO FOLLOW THIS WARNING MAY CAUSE INJURY OR DEATH AND CAUSE DAMAGE TO YOUR FIREARM.

WEBSITE INFORMATION

WEBSITE INFORMATION

An information resource for Winchester Repeating Arms can be found online at winchesterguns.com.

- List of Authorized Repair Centers.

- Customer Service information.

- Firearm Service/Repair Form.

- Answers to many technical and historical questions.

- Links to helpful sites.

24-WRA-250